Oxide fibre reinforced ceramics, so-called oxide ceramic matrix composites (O-CMC) are gradually becoming key strategic materials in multiple industrial applications, e.g. for use in next generation aero-engines, stationary gas turbines, power-to-X processes with concentrated solar power CSP, chemical industry, batch carrier for high temperature processes, etc. Today such high-end O-CMC components and the key raw material, the ceramic fibres as reinforcement component, are mainly exclusively produced in the United States. But as these are key components for the European manufacturing, energy and aerospace industry, there is a need to develop a European oxide fibre and O-CMC component industry, decreasing dependence on non-EU producers.

Project activities

The InVECOF project will provide a substantial contribution to sustainable product innovation through the following key activities:

| 1 | The development of a European oxide ceramic reinforcing fibre equivalent (ROF fibre) to US fibres and to establish it among end users in key industrial sectors. |

| 2 | The development and validation of a next-generation fibre in parallel with improved thermo-mechanical properties (NGO fibre). |

The ROF fibre will present an equivalent to the dominant 3M™ Nextel™ fibres with better availability, without dual-use export restrictions and lower price. The NGO fibre will have improved thermo-mechanical properties compared to the benchmark fibres in order to make processes, plants, turbines, etc. more energy efficient through higher application temperatures.

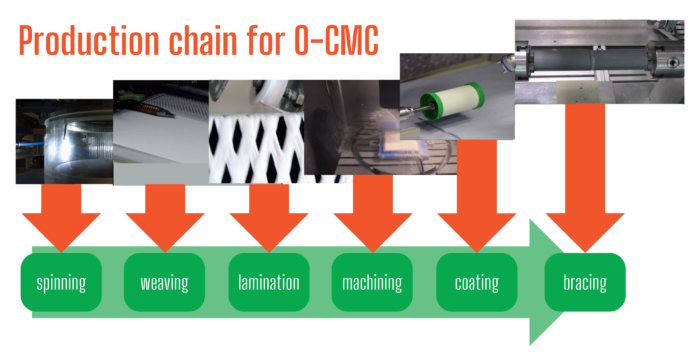

InVECOF “Innovative Value Chains for European Ceramic Oxide Fibres” covers the whole process chain beginning from fibre development and production over weaving these fibres to fabrics to O-CMC manufacturing – coupons and demonstrators for every end-user application – up to testing Ox-fibres and O-CMC components in relevant environments with project partners for every step.

Impact

InVECOF aims at creating a commercially available market within the EU for manufacturers of fabrics and O-CMCs. Both O-CMC manufacturers and industrial end-users will exploit these new fibres in their manufacturing due to their superior performance and ensured security of supply. Expected long-term impacts of InVECOF are:

Work packages

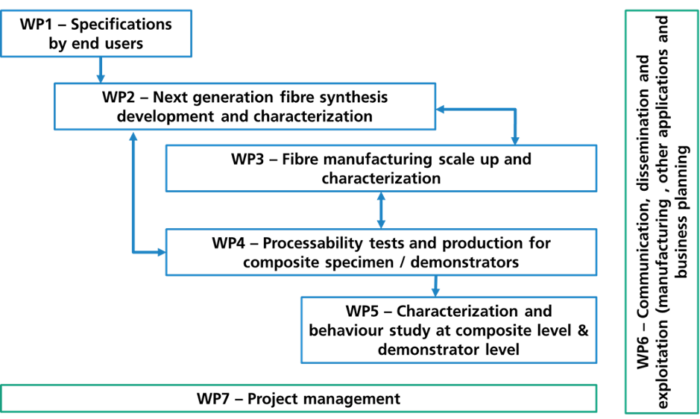

The structure of the work plan is divided into seven work packages (WPs), each targeting different objectives, tasks and expected results (See PERT diagram below). WP1 includes the preparatory work for the other WPs by specifying the needs of the end-users, meaning defining the properties and quantities of the fibres.

WP2 addresses next generation fibre synthesis development and characterization. This WP will address the development and upscale of next generation fibres. In parallel, WP3 will address the manufacturing capacity scale up and characterisation of the 3M equivalent fibre and ensure that the fibre production will be of a market relevant quality and quantity.

WP4 includes processability tests and the manufacturing of oxide fibre preforms and O-CMC coupons. WP5 includes the characterisation and behaviour study at composite level and demonstrator level.

The last two WPs (WP6, WP7) run in parallel with the whole project covering dissemination, communication, exploitation and business models as well as project management activities.